PRODUCTION MONITORING

We offer devices supporting the production management. We count on small recorders and displays making the pattern of work easier for the employees, and control of realization of tasks easier for the mangers. We promote, in the spirit of Kaizen, the monitoring of production on the level of the production floor where the work is executed. Local gathering of information and displaying the results in order to make production proceed harmoniously with the participation of the employees is important. We emphasize good visual presentations of events and results of work.

In fact, simple methods and small devices entail an advanced technique of recording and communication in the net, so the situations connected with production can be remotely followed, and data can be received and processed by production management systems.

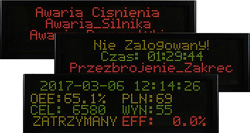

PRODUCTION MONITOR MP-240.

One device combines the functions of data acquisition and recording, estimating OEE indexes and ANDON type signalling. The production monitor both controls the processes and displays information of their course on a large screen.

Ready OEE arithmetic.

The monitor is working in the real time, keeping current calculations and recording several parameters describing effects and effectiveness of production processes. For instance, the number of good and defective items, level of efficiency and time of cycle. All occurrences are registered, such as delays and stoppages, as well as failures and scheduled interruptions. Thanks to this, coefficients and general effectiveness of OEE remains available. Complete detailed data prove very useful for further analysis, and the information found on the screen can be freely selected.

A screen at the user’s disposal.

A colour MP-240 screen can be used to design one’s own information windows, separately for the time of work, stoppages, failures and changeovers. Windows on the screen can be created as easily as tables in a spreadsheet. You adjust the cell sizes, put regular texts down and indicate numerical data from the list of variables enumerated by the monitor. You can define both the colour and size of the font, and also set up a warning against a change of colours when the variables go beyond established limits. Information on the screen can be read from the distance of several dozen metres.

Individual ANDON system.

According to the plan of work organization in every company, in the MP-240 monitor you can create a suitable tabular form for all occurrences, give them priorities and create text messages. Occurrences reported by operators are recorded and indicated on the screen. External signalling devices may be attached to control outputs of the monitor.

Virtual and real service.

All the functions of MP-240 monitor are available in the net through web browsers. An administrator and operators, in accordance with their authorizations, may perform remote configuration of the monitor, initiate its work and report occurrences. Service can be held only through a computer, partly or entirely without it when the monitor is controlled with the use of push-buttons and bar code scanner. The scanner may be used to start up the monitor, identify the operators and products, enter the data and report occurrences.

Net advantages.

Ethernet interface and the webserver of the monitor determine the possibility of dealing with this complicated device easily. Its whole configuration, current data and archival material are available as tables at many transparent built-in websites. Users needn’t install any additional software in their computers. They can use a viewer to start up the monitor, import data files, change the configuration, include the ftp service in an automatic recording of data on the server, and update the software. You only need to connect MP-240 to the net. There’s no fear, the monitor has a dedicated operation system resistant to web risks.

DOUBLE COUNTER/TIMER LDN57

It is monitoring the number of produced items, tact time and efficiency. It displays two selected parameters.

New double counters/timers with large tricoloured display and double reading support the production management. Digits

COUNTER/TIMER LDN57, LDN100

Universal counters and timers can be used to display the number of items produced and time measuring.

LDN57/100 have large LED displays which can change their colour and thus indicate exceeding set thresholds.

The “counter” function is used to count the number of items produced. Counted impulses may be transmitted by a sensor from the machine or from manually operated push button, pressed by an operator to report the completion of another item.

The “timer” function in this device can be used to take measurements of the time of operation (tact time) or tacting the work. In the first case the time is measured out from the making of the last item, and exceeding the time limit can be signalled by the change of colour of the reading. This reading is reset on the completion of the next item. In the second case – i.e. tacting – the timer works independently, setting the pace like a metronome. Completion of the tact may be signalled with the use of built-in control output. The counter readout is maintained in the case of power failure. LDN counters have durable housings of IP-54 category. They may include software individually adapted to the customer’s needs.